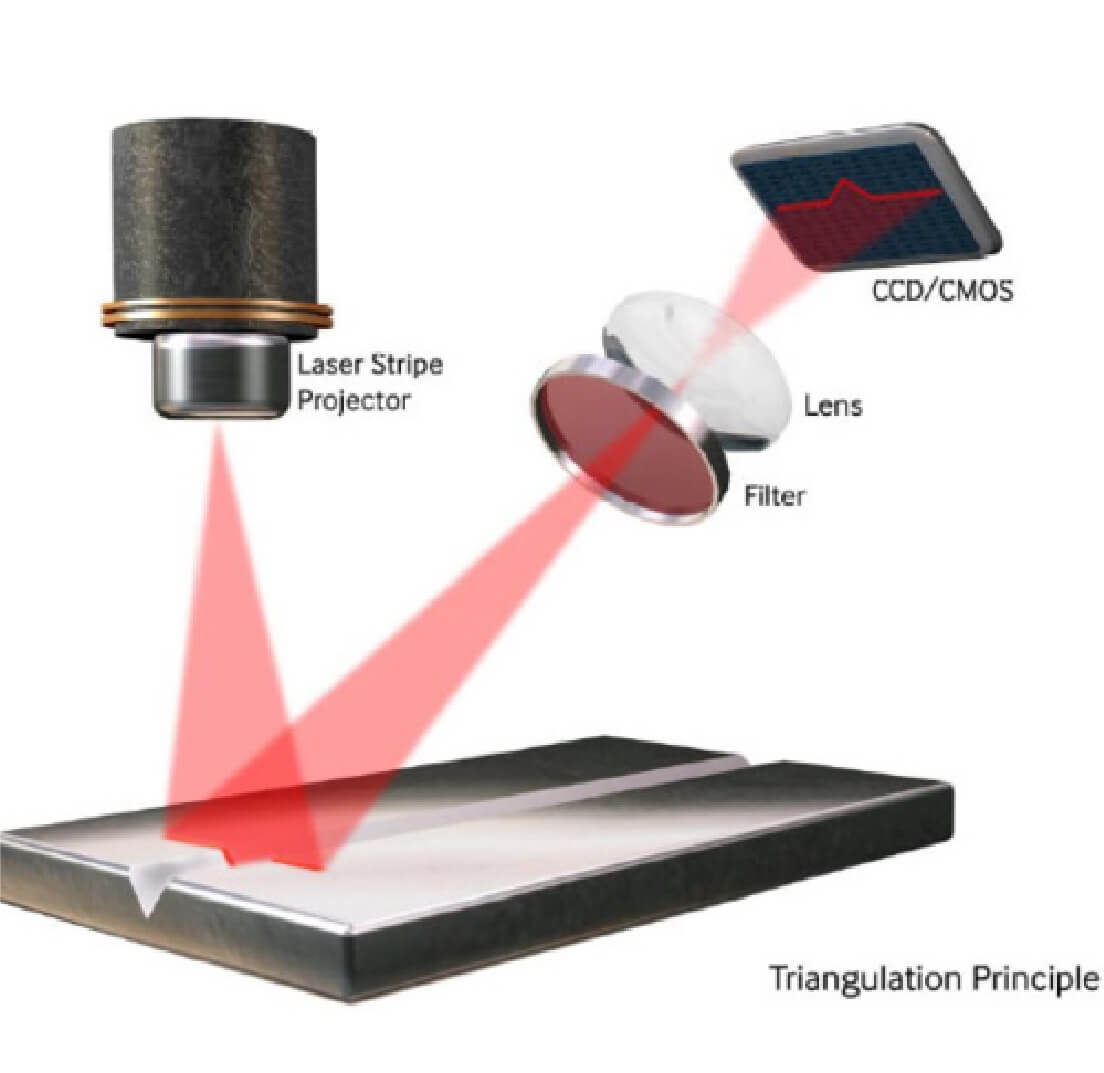

Image processing

Diverse applications for maximum precision

Our image processing solutions are used wherever maximum precision and efficiency are required. Whether for precise surface inspections, exact component measurements or reliable position corrections in real time, we develop customized systems that integrate seamlessly into your manufacturing processes.

From the automotive industry and electronics manufacturing to medical technology: With state-of-the-art software, intelligent algorithms and years of experience, we make your production smarter, faster and safer.

Experience high-tech image processing – directly adapted to your requirements.

Image processing software

Precision in perfection – with our image processing software

Our goal: the most precise measurement results for your production. Our high-performance image processing software delivers exactly the data you need for the safe, efficient control of your machines and robots – reliable, robust and industry-proven for years.

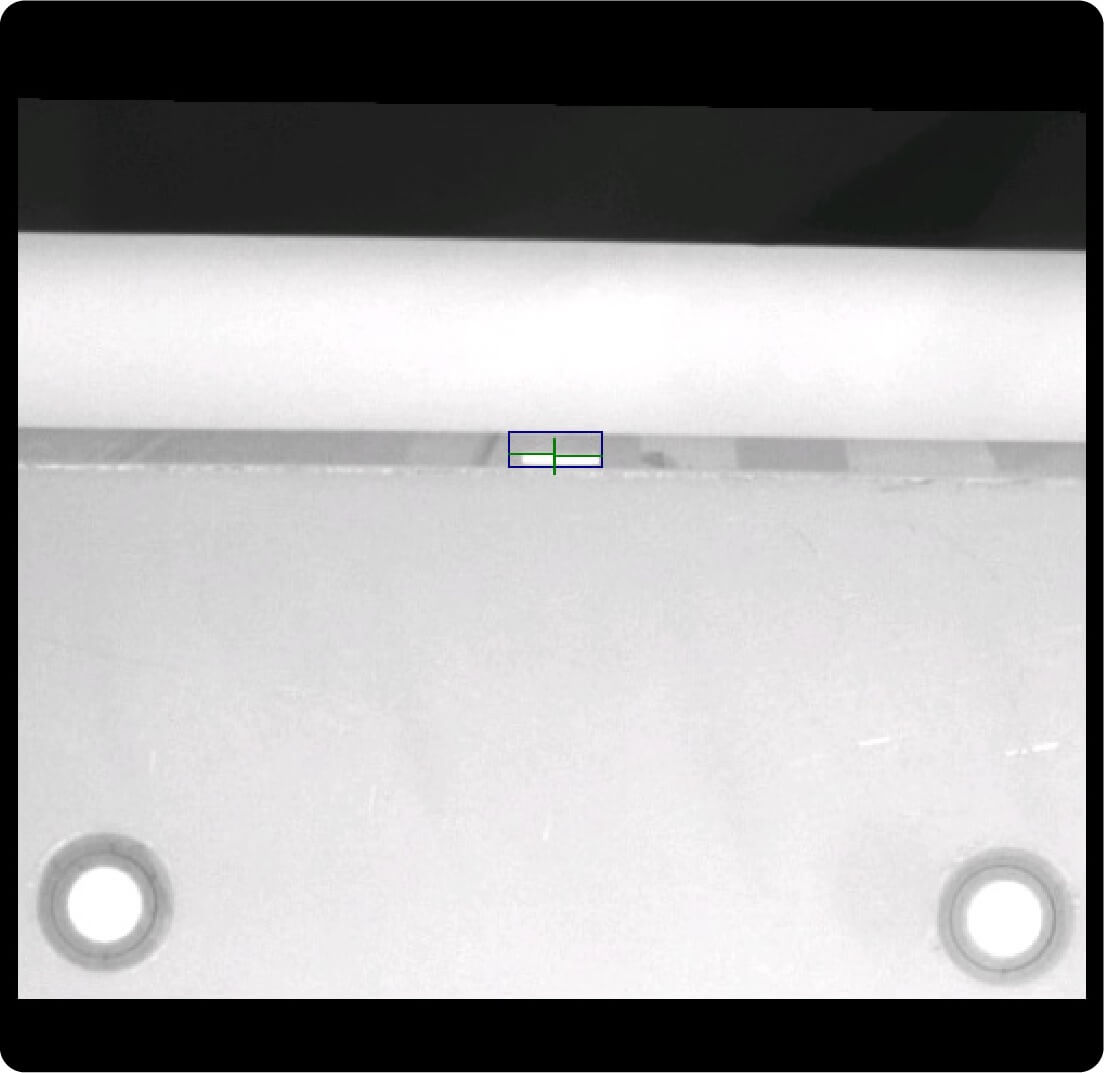

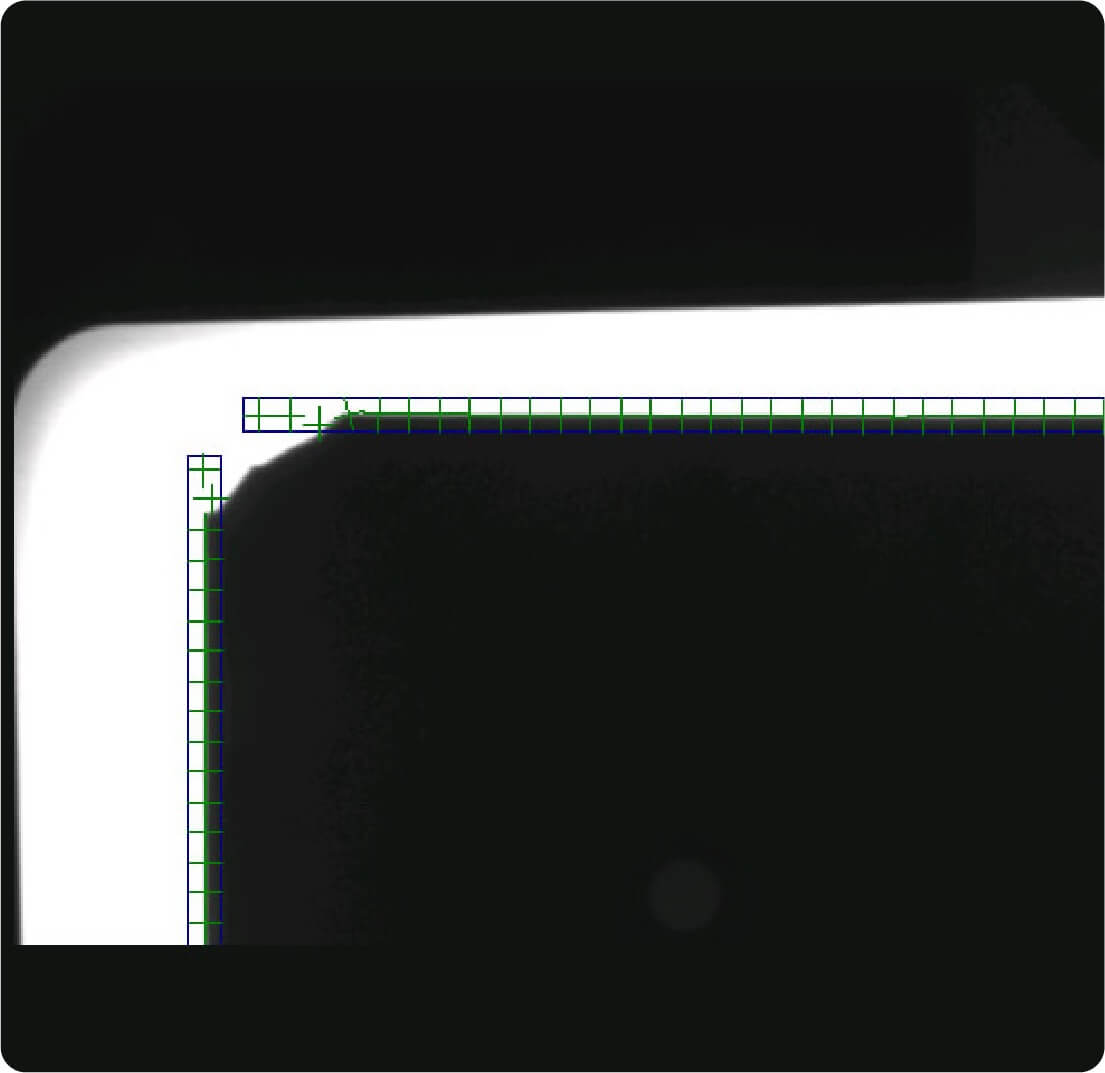

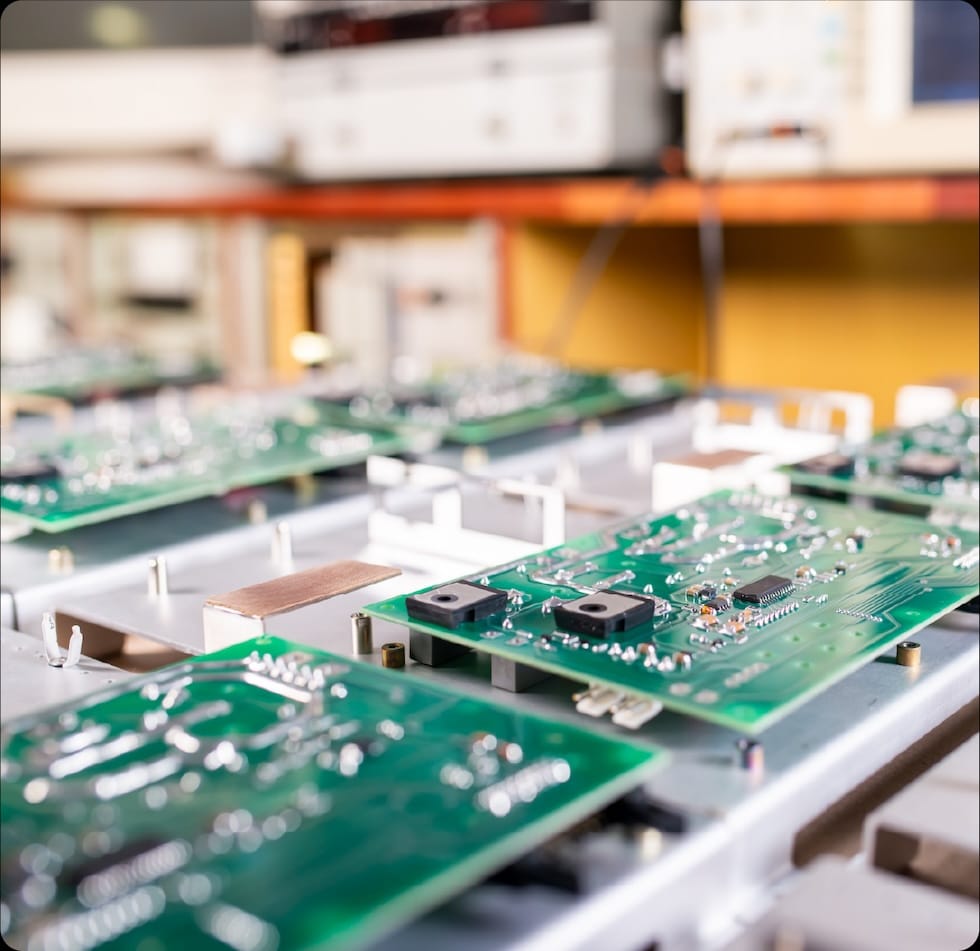

Image processing software for printed circuit boards

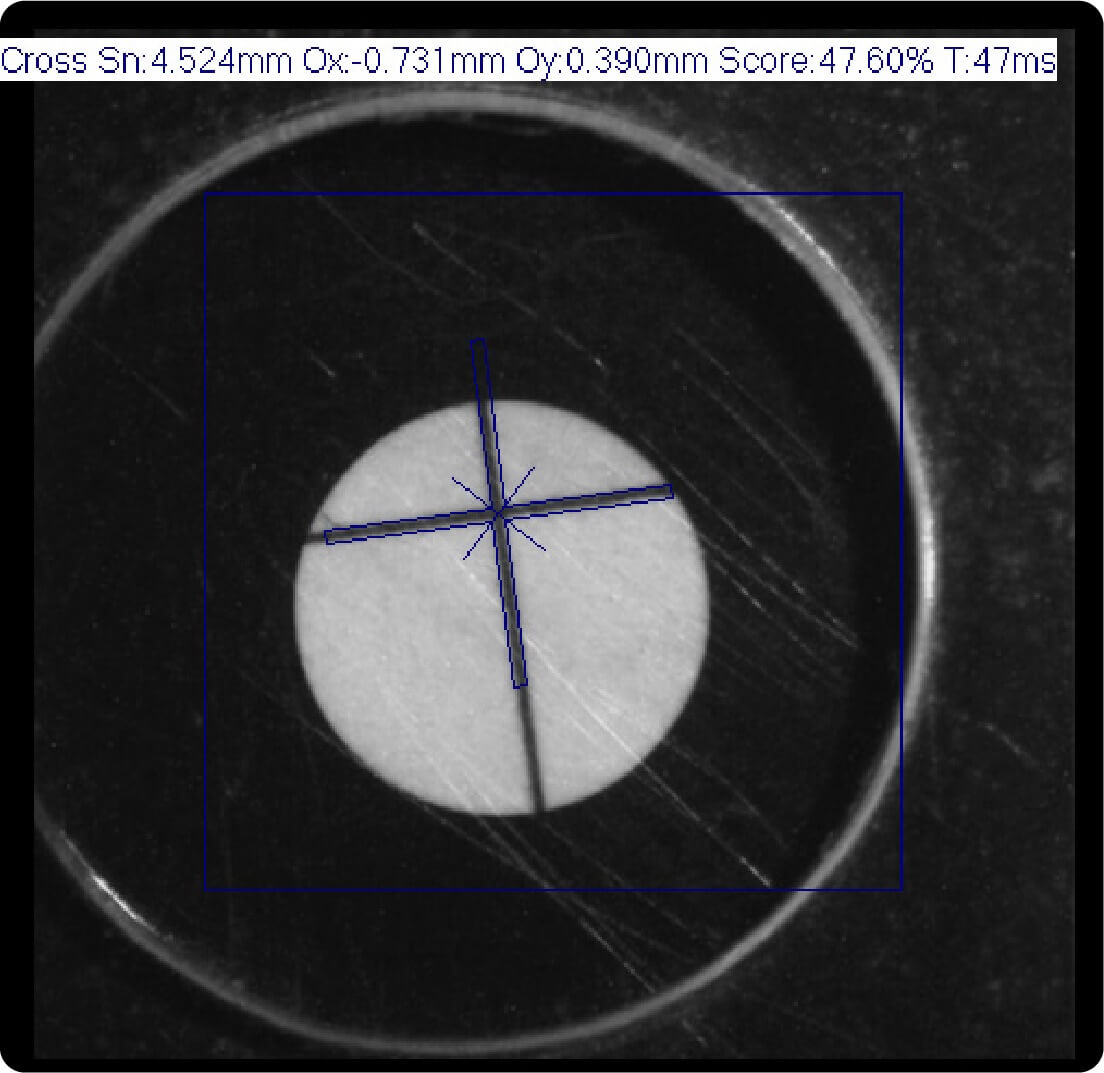

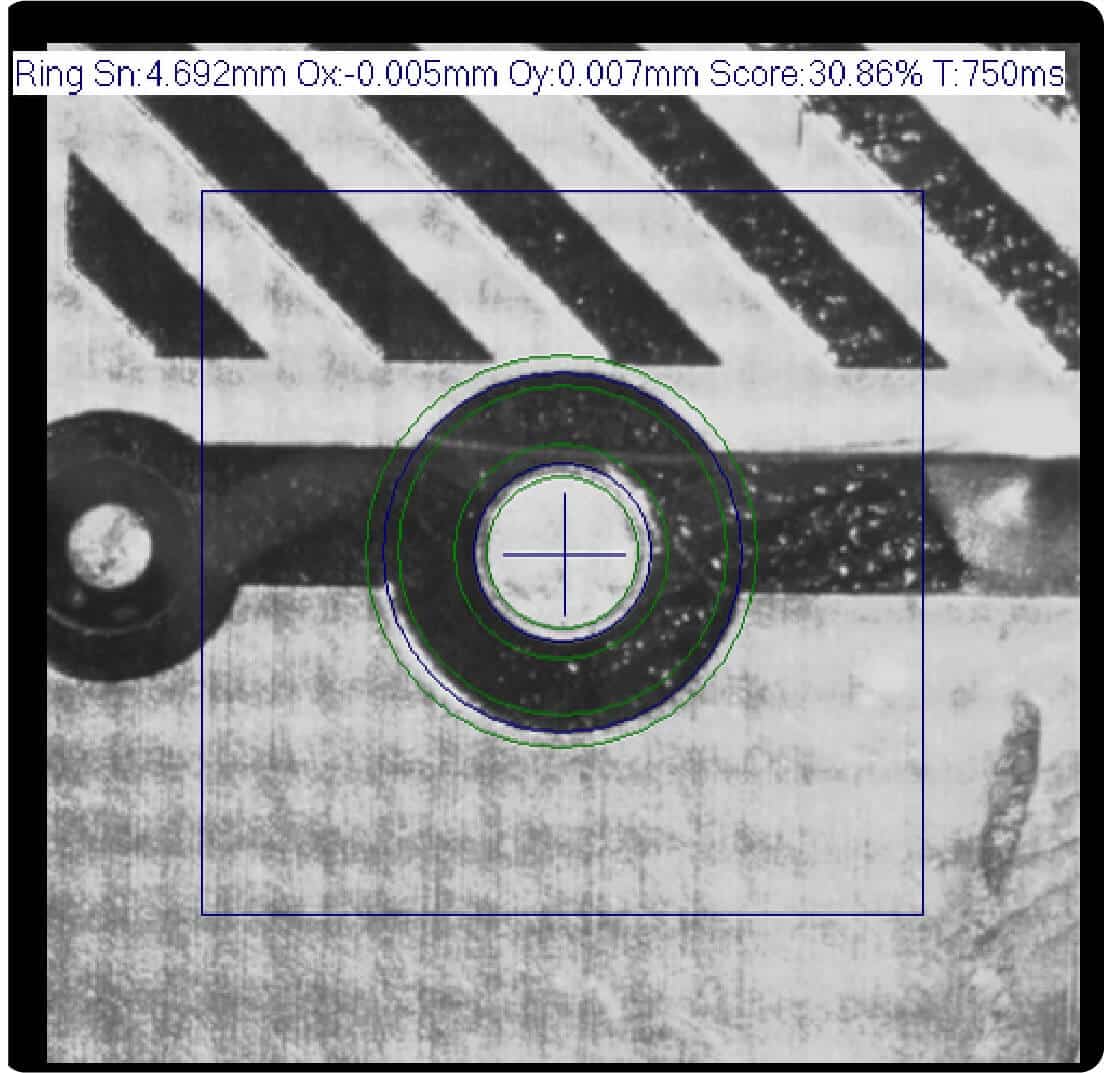

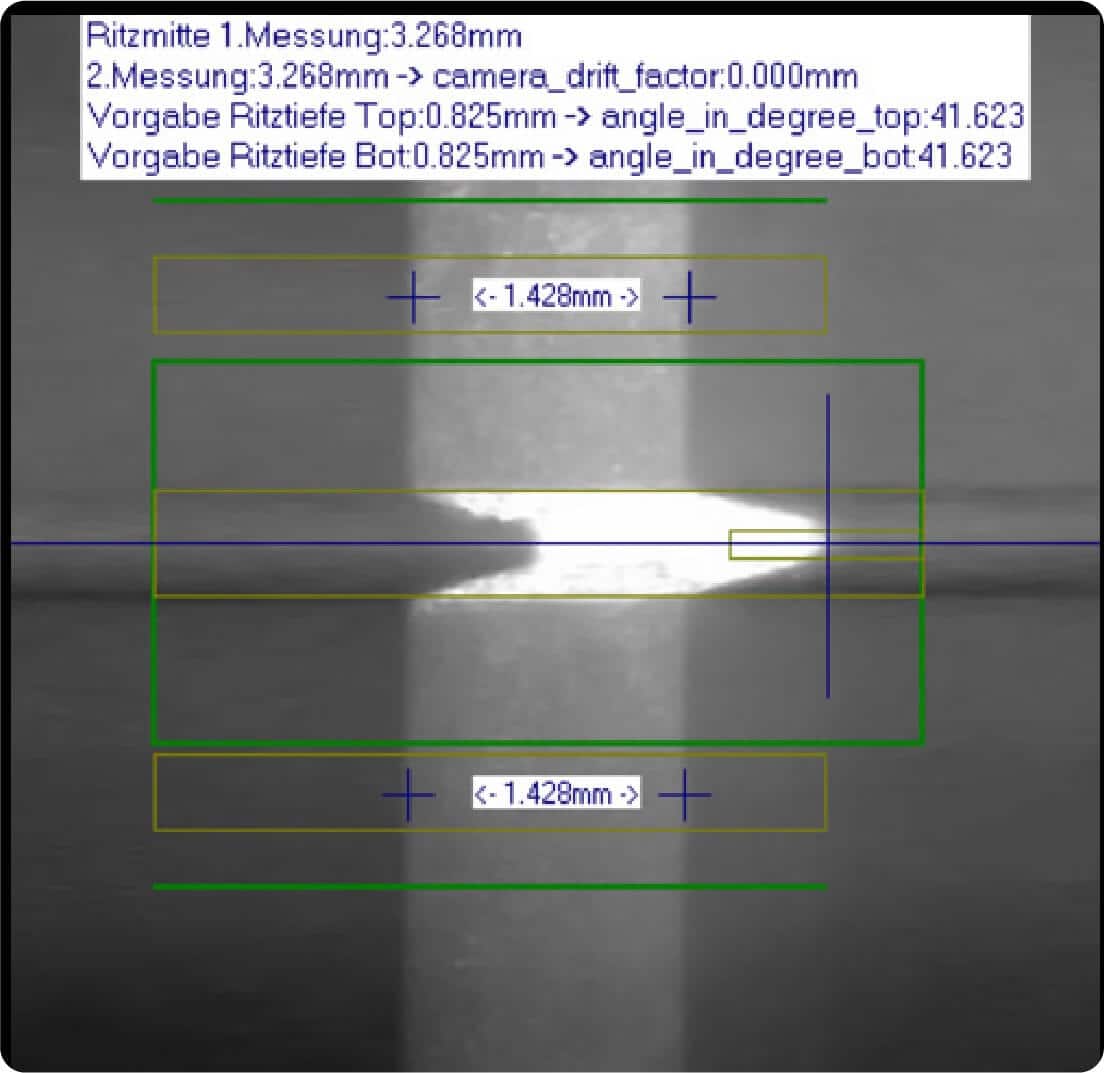

The intelligent solution for printed circuit board machines of all types.

Whether drilling, milling, exposing or scribing: analysis of measurement marks, recognition of barcodes and delivery of high-quality correction data for maximum production quality – even under X-ray conditions.

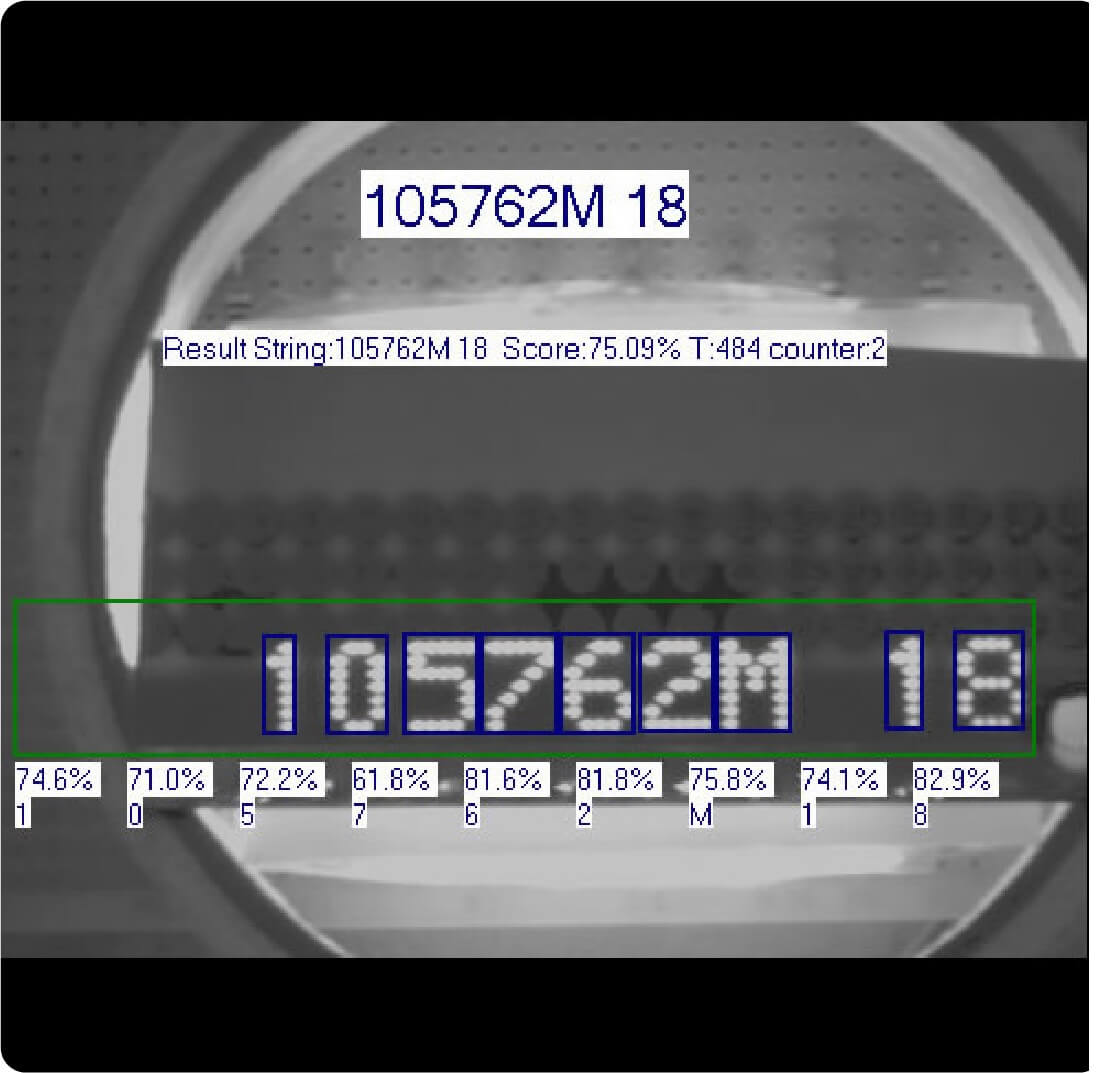

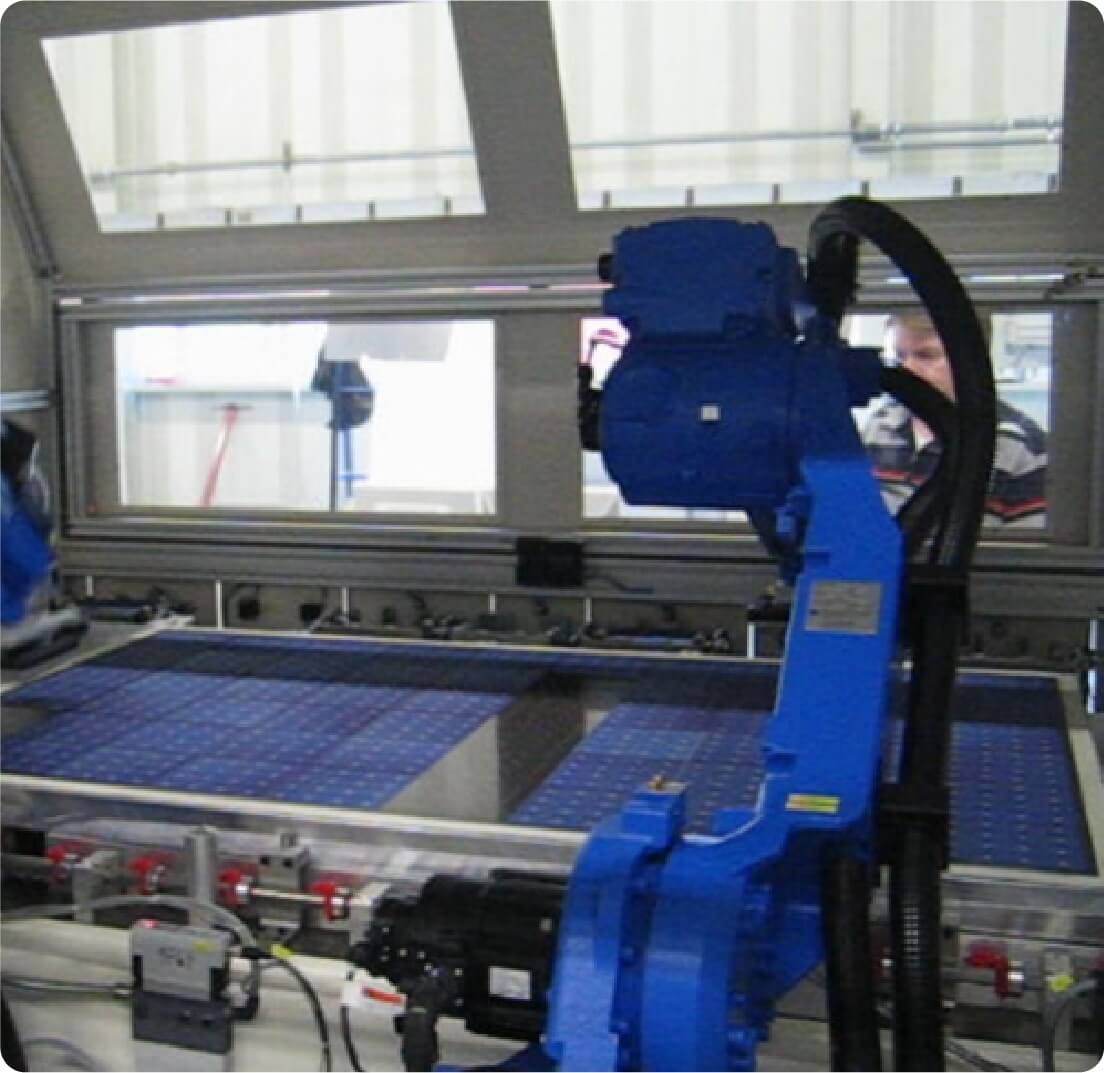

Image processing software for Robot vision

Perfect for handling robots and automated manufacturing.

Recognition of barcodes, data matrix or QR codes, inspection of good/bad parts, measurement and positioning of components reliably and precisely – with seamless Machine communication.

Efficient. Flexible. Industry-proven.

Discover how our image processing software can make your production more intelligent.

Contact us – we will advise you personally!

Data analysis

lighting systems

Keep an eye on your production at all times. Our customized software delivers real time data, visualizes all relevant processes and supports you in optimisation. With individually customizable Dashboards, you can identify bottlenecks early on and make informed decisions – quickly, transparently and reliably. This increases the efficiency, quality and economy of your production.